Historic and custom fittings, produced using traditional sand-casting processes – our individual door fittings are designed, developed and fabricated at the Glutz Manufactory. Spanning the timeline, the production range includes different styles from baroque to the no-frills architectural style of today. Whether a replica of a classic historicist fitting, a brass rosette for the door of an old church, discontinued models from the late 19th century or a modern new product development – anything is possible at the Glutz Manufactory.

Fittings from the Glutz Manufactory

From conception to the completed door fitting

Our expert personnel accompany you through the entire process, from original design to the finished fitting. As a point of contact for architects, interior designers, planning bodies, fabricators, builders, cultural heritage preservation organisations and designers, we create unique pieces and ranges as part of a guided process.

Replicas

Casting of the original model or an existing cast model from our extensive collection of 12,000 cast models for door, window and furniture fittings.

New development

The process for new fittings is made up of three individual stages:

Design

- Design of individual or personalised fittings for doors, windows and furniture

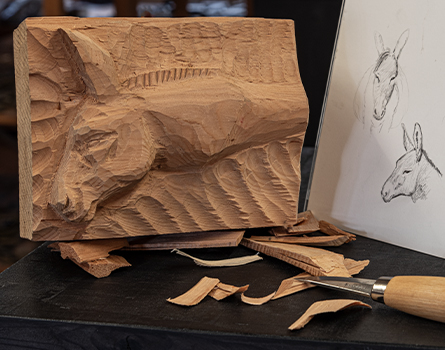

- Design development using sketches and models

- Production of cast models by wood carvers or using CAD drawing and 3D-printing procedures

- Implementation in brass or bronze

Engineering

- Development of standardised fittings for use in historical or listed buildings, as well as for individual designs

- Devising of solutions for applications with requirements relating to break-in protection and emergency exits

- Individually designed fittings, based on break-in protection classes ES1, ES2, ES3

- Integration of the Glutz eAccess electronic access solution in historical fittings

- Integration of proven Glutz technologies, including glide bearings, retaining springs or fixed mobile latch assembly

- Test reports or certificates pursuant to EN1906, EN1907, EN1627-30, DIN or ÖNORM (Austrian Standards)

Implementation

- Manufacture of fittings made from brass or bronze in our own in-house foundry

- Surface finish: matt-finished, polished, burnished, patinated, nickel-plated, gold-plated, painted or powder-coated brass or bronze

- Packaging: in accordance with customer specifications

Care instructions

References

Join us on a journey through time to discover some of our previously completed restoration, renovation and innovation projects.